Background

Aliaxis is a global leader in advanced fluid management solutions, specialising in enabling access to water and energy. With a strong focus on innovation and sustainability, Aliaxis provides a wide range of products and services to meet the needs of various industries. Their expertise and commitment to excellence have made them a trusted partner for organisations worldwide.

Aliaxis has established a site in Lenham, Kent, as part of its global operations. This strategic location allows them to serve their customers in the region more efficiently and effectively. The Lenham site serves as a hub for Aliaxis’ activities, including manufacturing, distribution, and technical services. By having a presence in Lenham, Aliaxis can better cater to the needs of their clients in the area and provide localised support and solutions.

Problem

The site in Lenham, Kent, was in need of an upgrade to incorporate fibre connectivity throughout the premises. This upgrade was essential to enhance the site’s ability to have a seamless network across its various areas. By implementing a fibre solution, Aliaxis aimed to improve communication and data transfer between different departments and ensure a reliable and high-speed network infrastructure. This upgrade would enable efficient collaboration, streamlined operations, and enhanced productivity throughout the site.

Aliaxis selected MPR as their network provider for the Lenham site because MPR’s approach aligned with their requirements for a single provider to guide them from solution design to implementation. MPR’s expertise in technologies like Air Blow Fibre allowed them to design and install flexible, future-proof systems. With a proven track record of delivering dependable infrastructure to similar clients, MPR demonstrated their understanding of the complexities of clients like Aliaxis.

Solution

MPR’s highly skilled team covered all key elements and service requirements, including networking design, hardware procurement, physical installation, project management, qualified team members, documentation and CAD work, and ongoing support.

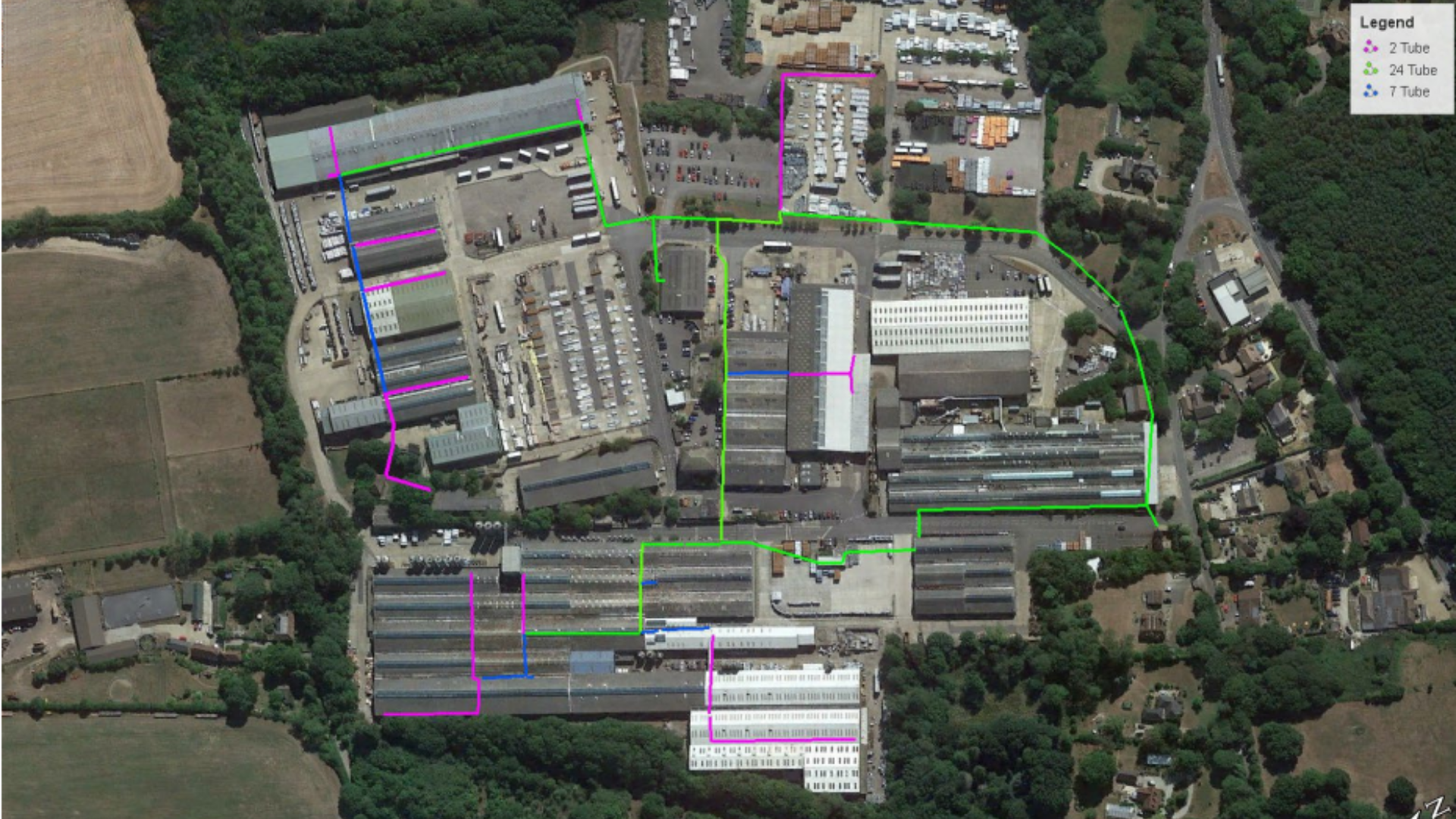

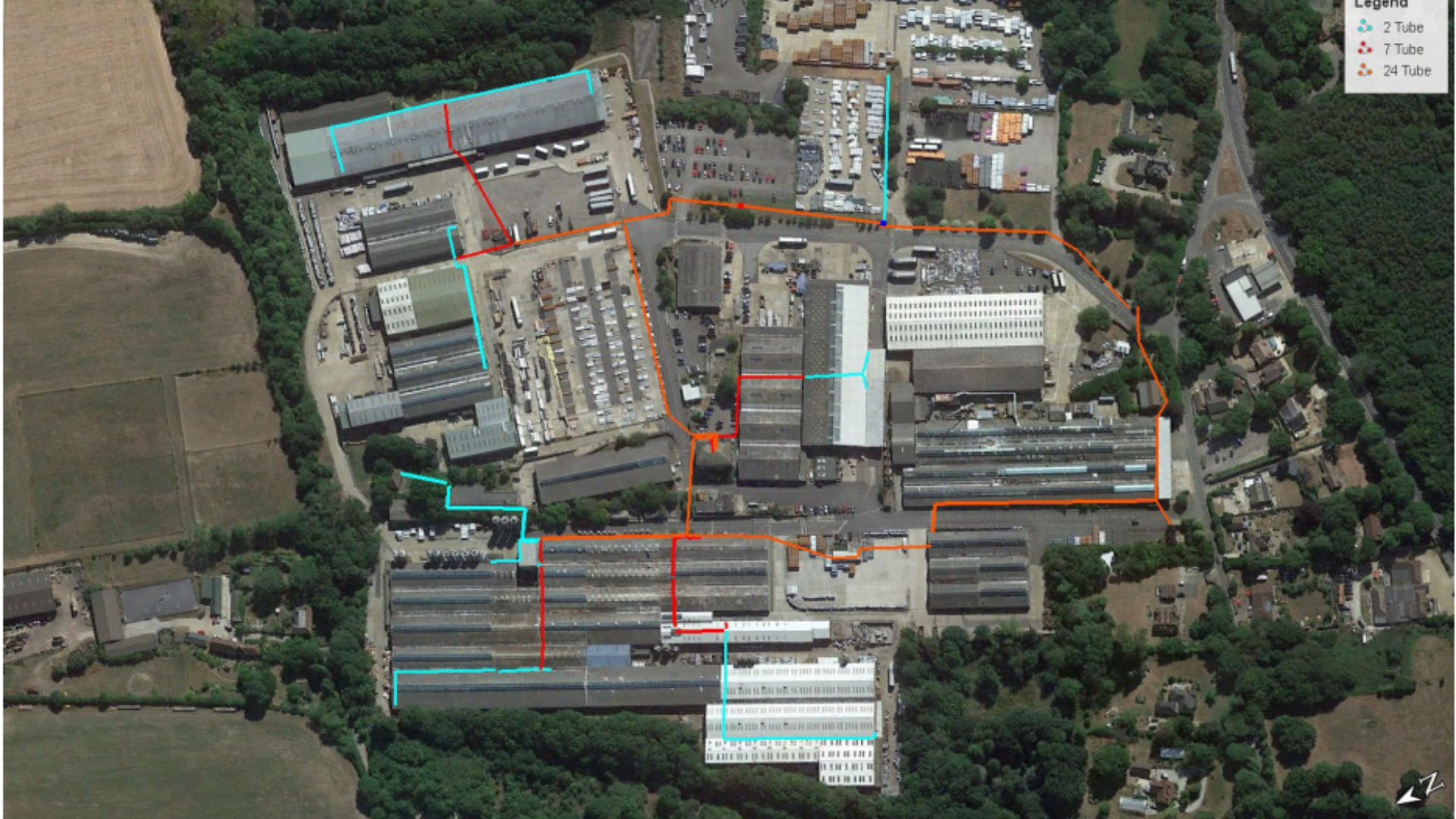

For the proposed upgrade of Marley’s main site backbone fibre network, MPR recommended using an Air Blown Fibre (ABF) solution. ABF systems offer cost reduction, increased design flexibility, and the ability to switch between fibre types as needed while prioritising ease of installation. This system uses small ducts, the micro ducts, that are used to blow the bundle of fibres inside them, using compressed air. These bundles of fibres are lightweight and easy to transport and store. The microducts bundles can be easily split and it’s possible to drive each one, to a different route. The fibres can be blown using these tubes, to facilitate the distribution without splicing and creating a point-to-point installation.

The main advantages of the air blown fibre system

-

Flexibility – The main advantage of using an air blown fibre cable is the flexibility. If the technology changes and we need to change the type of fibres deployed, we simply have to pull out the existing fibres and blow the new type in the same microducts.

-

Cost of installation – The cost of installing air blown fibre cables is more or less the same as the traditional cable. The fibres and the microducts may be more expensive than the traditional cables but the lower numbers of splices required in the ABF system and the deployment will balance the costs in the end. The main advantage in terms of costs, is the capacity to deploy more fibres in the same tubes if needed. For example, if it’s needed to replace the fibre technology to a new one.

The ABF solutions also tackles the last 2 expected benefits from the original project plan for better network resilience and simplified management and provide additional capacity and room for future growth.

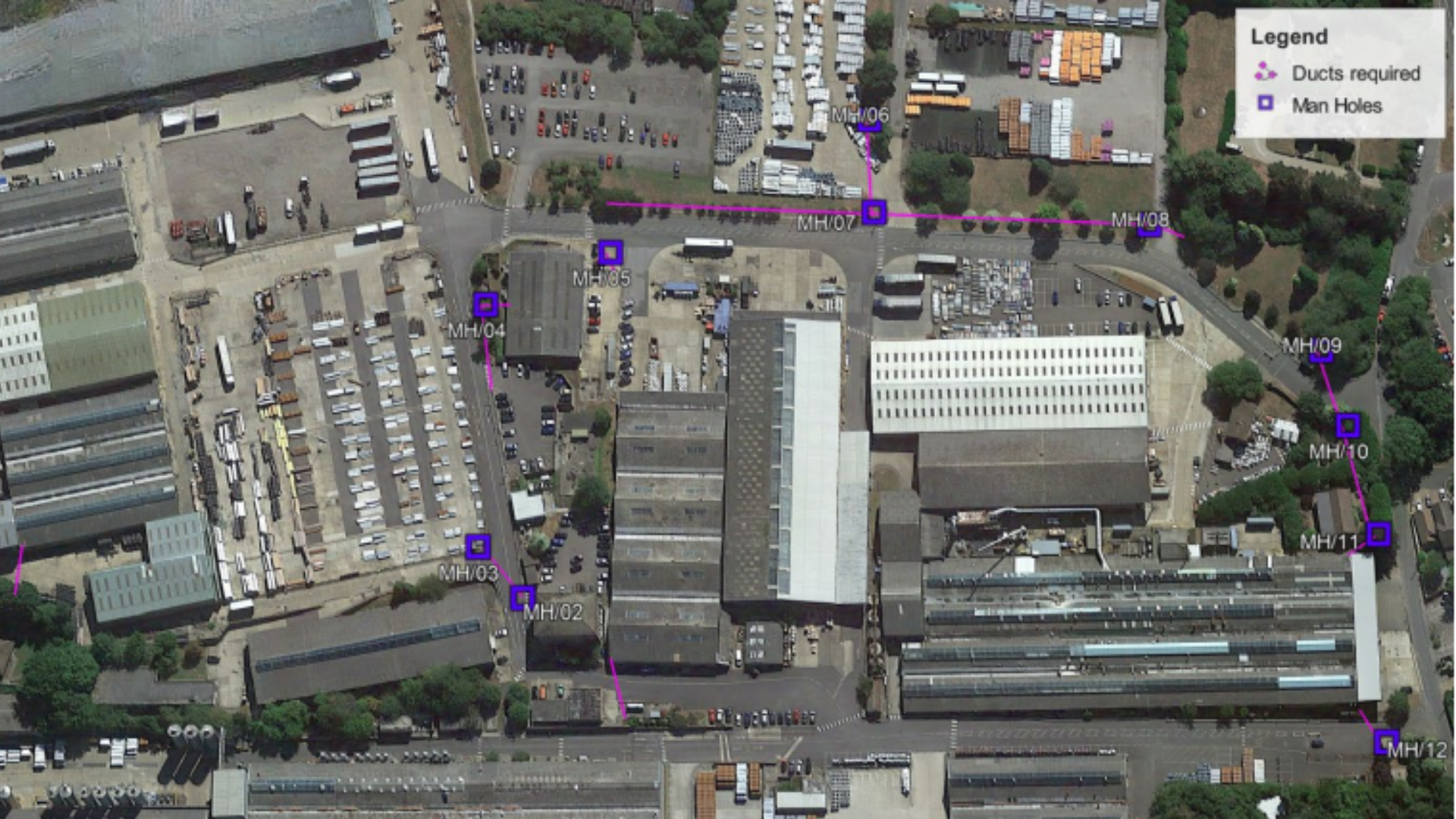

MPR implemented a comprehensive fibre installation plan at each core cabinet, utilising a 25 Tube duct that was strategically split into multiple 12 tube ducts and eventually leading to a 2 tube duct for each cabinet. Once the blow tube was in place, a 12 core fibre was blown from each core to every cabinet in a single run, allowing for efficient splicing and termination as required. MPR also accounted for the necessary infrastructure, including 21u wall-mounted cabinets with a width and depth of 600 at each location, as well as 4 floor-standing 42U 800×1000 cabinets to accommodate the project’s needs.

Results

The implementation of the air blown fibre system by MPR at the Marley site in Lenham, Kent, has yielded significant results. The use of micro ducts and lightweight fibre bundles blown through compressed air has provided enhanced flexibility in the network infrastructure. This flexibility allows for easy replacement or addition of fibres without the need for splicing, ensuring future scalability and adaptability to changing technology.

The project has also demonstrated cost-effectiveness in terms of installation. While the initial investment in fibres and microducts may be higher compared to traditional cables, the reduced number of splices required in the air blown fibre system helps balance the costs. Additionally, the system’s capacity to deploy more fibres in the same tubes provides room for future growth and technology upgrades.

The improved network resilience and simplified management achieved through the air blown fibre solution have been key outcomes of the project. By installing 25 Tube ducts, strategically splitting them into multiple 12 tube ducts, and eventually leading to a 2 tube duct for each cabinet, MPR has ensured efficient fibre distribution. The single-run installation of 12 core fibres from each core to every cabinet has streamlined the network infrastructure, allowing for easy splicing and termination as needed.

MPR’s meticulous planning also included the provision of suitable cabinets, such as 21u wall-mounted cabinets with a width and depth of 600 at each location, and 4 floor-standing 42U 800×1000 cabinets. These cabinets offer the necessary space and organization for housing the network equipment effectively.

Overall, the project’s successful implementation of the air blown fibre system has resulted in a highly flexible, cost-effective, and resilient network infrastructure at the Marley site, meeting the specific requirements of Aliaxis and positioning them for future growth and technological advancements.

If you are seeking to enhance your connectivity with blown fibre technology, we invite you to contact us. Our highly skilled team at MPR Technical Services specialises in designing and implementing advanced fibre solutions that offer flexibility, cost-effectiveness, and improved network resilience. Don’t hesitate to reach out to us for expert assistance in upgrading your connectivity infrastructure.